No products

FAQ - FREQUENTLY ASKED QUESTIONS

What is CMYK Digital Printing?

Digital print refers to a method of printing utilising a combination of CMYK inks or Cyan, Magenta, Yellow & Black which do not require films and plates to lay down. This allows for flexibility in number of sku’s, images, variable data printing and the reduction of costs and lead-times as your artwork can go straight from PDF to press without the need to wait for additional tooling.

How should artwork be supplied?

Our preferred method for artwork is high-res PDF however please see our Artwork Setup Guide for further information. If you have existing labels that were printed elsewhere or a specific colour you would like us to match, please send us a sample or specify the PMS and we will match the colour as closely as possible through our CMYK Digital technology.

What payment methods are accepted?

Onpack accepts cash, bank transfer and most credit cards. Once your first order with us is complete you may also apply for a 30-day trading account with Onpack using our credit application which is downloadable here.

Can a sample be provided prior to printing?

Onpack offers press-proof prints and mock-ups prior to the printing of your full label run to ensure complete customer satisfaction on sizing, material and colour. This is also a great option for new product pitches or launches to test the market prior to larger-scale manufacture. Please see our Why Digital? page for more information.

How long will it take to receive my labels?

Due to the speed of our state-of-the-art press and finishing units, Onpack can have your labels printed, packed and delivered within 5-7 working days from when you approve your artwork to print. Deliveries locally in Melbourne will arrive same-day, with regional Victoria, NSW, SA, QLD, WA and NT delivering overnight.

What is a die-cutter?

A die-cutter is the tooling used in the finishing machine which cuts your labels to shape/size and then allows for the waste to be stripped away from around the label, leaving you with clean-cut labels supplied on the roll which are easy to peel away from the liner. We have a range of basic shape pre-existing dies that can be utilised for your labels and can be found free to download on the Our Standard Sizes page. We also cater to any labels that have a special or unique shape or require a size we do not currently have on hand will have new tooling purchased to suit.

What are winding directions?

The winding direction determines which direction we supply your labels off the roll. This can assist in making application easier for manual or hand application and can be critical for machine application. High-speed automated machines and semi-automated machines will have certain specifications and requirements for which direction the label must be supplied to ensure they apply on to the product right-way up. Please see our Winding Directions Chart for further information.

What is the minimum order quantity?

Technically there are no minimum quantities for digital printing as it is perfectly suited for short, medium and long runs however we do recommend increasing your orders to at least 500 in order to gain the best economies of scale.

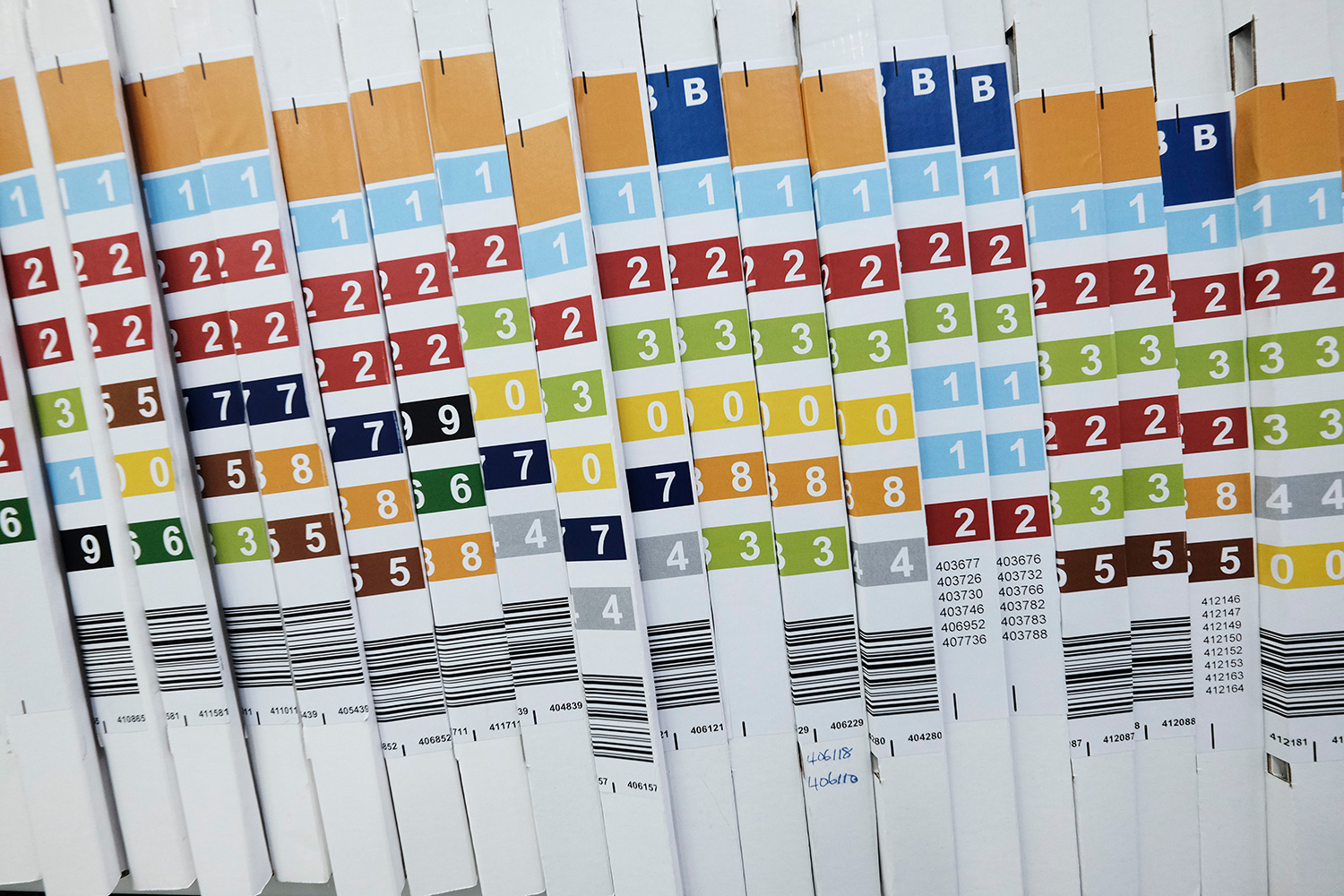

Can my labels be sequentially numbered or have variable information?

Yes, our digital printing technology allows for variable data information and sequential numbering of your labels. We can cater to variable batch and expiries, numbering, variable pricing etc. however the variable information must be printed in one colour black only and supplied to us in spreadsheet form to allow for ease of set-up during the Pre-Press and artwork formatting processes.

What finished formats do you supply the labels in?

Onpack has capabilities for supplying labels on rolls, as singles and in sheets. When purchasing labels in rolls, we can supply rolls with any number of labels to suit your labelling requirements. Depending on the size of the label, the standard number per roll for hand or manual application can be between 200 – 1000 labels per roll, and machine application will have a maximum roll diameter requirement, usually between 100mm – 400mm. If you have purchased a labelling machine or will be labelling through a mobile or professional application company, please advise their specifications and we can supply your rolls to suit.

Can I have a perforation?

Yes, we can perforate not only through your label for “tear here” and tamper-evident requirements but can also perforate through the liner to assist in ease of tearing so that they can be utilised as singles off the rolls for ease of distribution and convenience.

Loading...

Loading...